Saint Gobain Vinyl Sidings

Vinyl Sidings are external wall-cladding products. They are the most popular cladding material in North America and now are available in India too. It is being increasingly preferred across the globe, for their many technical advantages and superior aesthetic appeal.

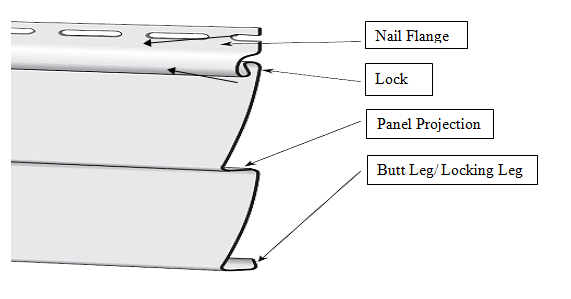

Sidings are Poly Vinyl Chloride (PVC) materials to which several processing aids have been added to enhance their performance. They come in the form of panels. Each panel is 8 inchesx12 feet long.

They can be conveniently installed onto a vertical surface-RCC/wood/fiber cement board/gyp-board etc.

Please scroll down for detailed Product Description, Advantages, Available Designs and Patterns and Application Procedures.

Product Description

Siding is a cladding material which is mounted onto a vertical wall surface generally with the help of anticorrosive fasteners.

- First introduced in 1960s

- Rapid popularity in US & Canada in last 4 decades

- No. 1 choice amongst homemakers for external cladding; twice more than other materials

- Entire range of accessories available

Vinyl Sidings – Composition

- PVC (Poly Vinyl Chloride)

- Forms the bulk of composition (Almost 80%)

- Thermoplastic in nature

- Micro Ingredients – Pigment,TiO2, Calcium Sterate

- Pigments or colours are added to enhance appearance

- TiO2 (Titanium di oxide) is added to prevent UV degradation

- Calcium stearate aids in uniform blending of PVC compound and produce a uniform finish to resist cracking

- Processing aids – Waxes, Impact Modifiers, Acrylic Processing aids, Stabilizers

- Waxes – To prevent adhesshion of PVC resin to extruders and impart gloss

- Impact modifiers – To impart strength and robustness

- Acrylic Processing aids – Improves Durability and consistency

- Stabilizers – Prevents degrading of PVC during manufacturing process (Heating and high pressure)

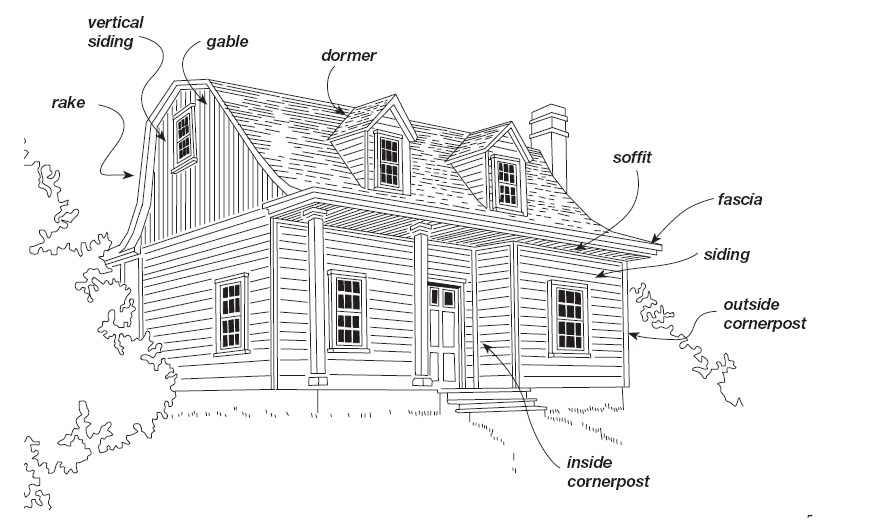

Components of a typical house

Typical Siding components

List of commonly used accessories

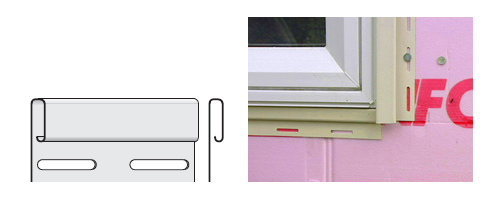

Starter Strip:

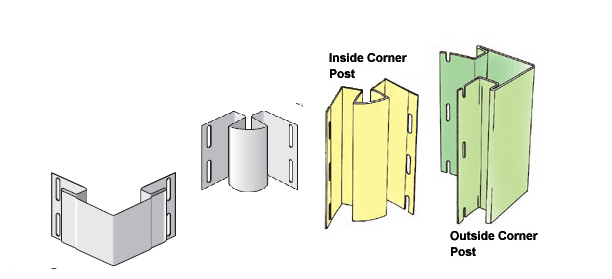

Secures the first course of sidings to the home.Corner Post:

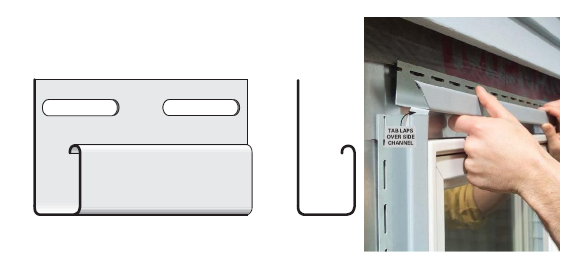

Used where Sidings meet Outside / Inside CornerJ-Chanel:

Used as Universal Sidings receiving channel for use around utility openings, under eaves etc.

Undersill Trim:

Helps secure trimmed Siding panels under windows and eaves.

Advantages of Sidings

Key Advantages

- Aesthetics

- Waterproof

- Lifetime Fade protection

- Zero maintenance

- Choice of multiple colors

- Does not peel, flake, rust, rot

- Rated No. 1 brand by Building Professionals in USA

- Colour does not fade

- Does not peel off, flake or crack

- Scratches do not show

- Resists denting from day to day occurrences

Installation Proficiency

- Installation Proficiency Patented STUD finder™, ensures accurate & secure installation

- Patented secure intra panel interlock

- Made to fit accessory range

- Light in weight and Flexibility – Aids easy handling/ transportation and fast application

- Incurs less damage at work site hence less wastage

Added Advantages

- Withstands wind load pressure of 135 mph

- Class 1 (A) fire rating

- Does not conduct heat or cold

- Does not magnify sound of rain or hail.

Application Procedures

Application Procedure for Vinyl Sidings

Wall surface preparation

– The surface should be leveled to plumb. It should be completely and free from undulations, loose debris etc.Application of aluminum battens

– Aluminum channels (1’x1’ for walls and 3’x1’for corners) have to be fixed vertically, spaced at 16″ center to center.Application of Corner Posts

– Outside and inside corner posts, is to be fixed respectively, at all the corner junctions. Only the prescribed corrosion-resistant nails (Special Head size of 8mm – 9mm and 1” long), by the manufacturer are to be used for the application.Application of Starter Course

– The starter course is to be horizontally fixed at the bottom of the wall (a min gap of 1/4″ from the ground is to be left).Application of Siding Panels

– Vinyl sidings panels of the selected design, type and color shall be fixed on to the channels. The application starts at the base of the wall at the starter level and goes on to the soffit of the roof. The nails have to be driven at the center of the nailing slots to accommodate temperature movements.Application of Accessories at junctions and openings

– J channels and other finishing accessories shall be applied to properly terminate sidings at all junctions and openings to receive the sidings.Basic Tools Required

Snap Lock Punch:

A snap lock punch is used to punch lugs in the cut edges of siding to be used for the top or finishing course at the top of the wall, or underneath a window.Nail Hole Slot Punch:

Occasionally, it may be necessary to elongate a nail hem slot. The hole is elongated for expansion and contraction.